Rotary Roll Forming

Experience unmatched efficiency and precision with Grotnes' advanced roll-forming technology,

tailored to meet your production needs.

Rotary Roll Former Applications

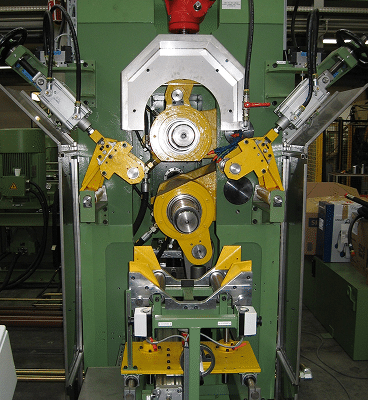

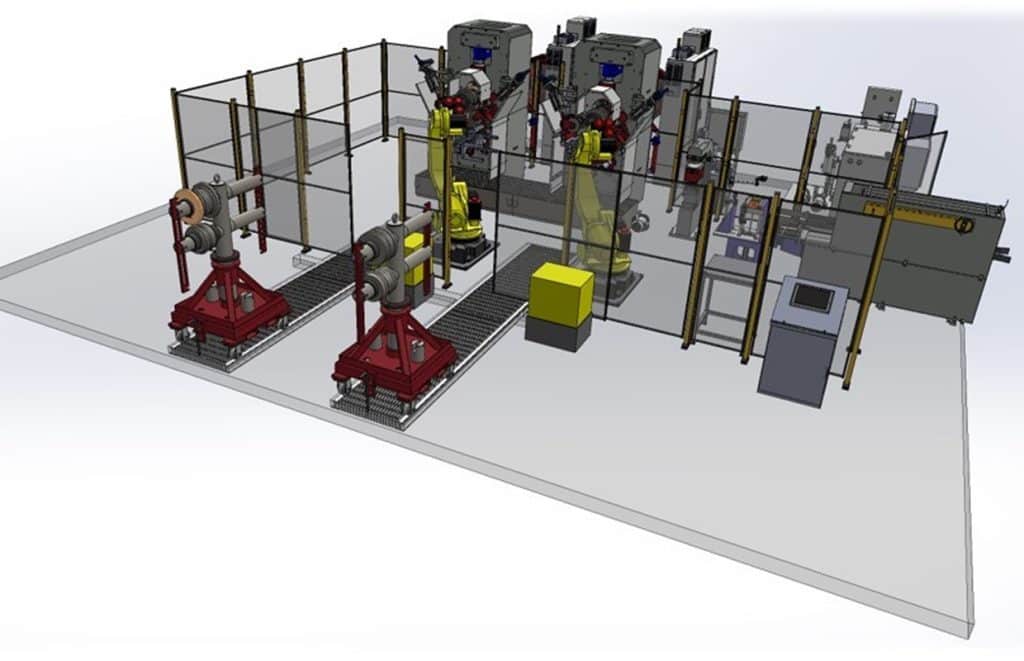

Grotnes rotary roll forming is a precision, cold-rolling process that efficiently forms profiled configurations with close tolerances. This method is ideal for creating cylinders, conical shapes, hoops and rings, and is particularly effective when producing parts of varying diameters but with identical profiles, significantly reducing tooling costs and setup times.

- Steel Drums

- Appliance Drums

- Wheel Rims

- Brake Drums

- Jet Engine Components

Features

- Modular Design

- Recipe Driven

- All-Electric Drive

- Quick-Change Tooling

- Manual & Fully Automatic

Quote-to-Ownership Process

1. Request a Quote

Begin your journey by reaching out to Grotnes to request a detailed quote. Provide specifics about your metalforming needs and the types of materials you will be working with, allowing our team to tailor the machinery options to your requirements.

2. Consultation

Engage with our experts during a comprehensive consultation to refine your machinery specifications and explore additional features and customizations. This step ensures the equipment you choose perfectly aligns with your production goals and operational demands.

3. Finalize & Install

Once you approve the final specifications and quote, we’ll proceed with the manufacturing of your customized metalforming machinery. After production, Grotnes will coordinate the delivery and installation, ensuring everything is set up to operate seamlessly within your existing processes.