Integrated Automation

Improve your production with Grotnes' cutting-edge automation solutions.

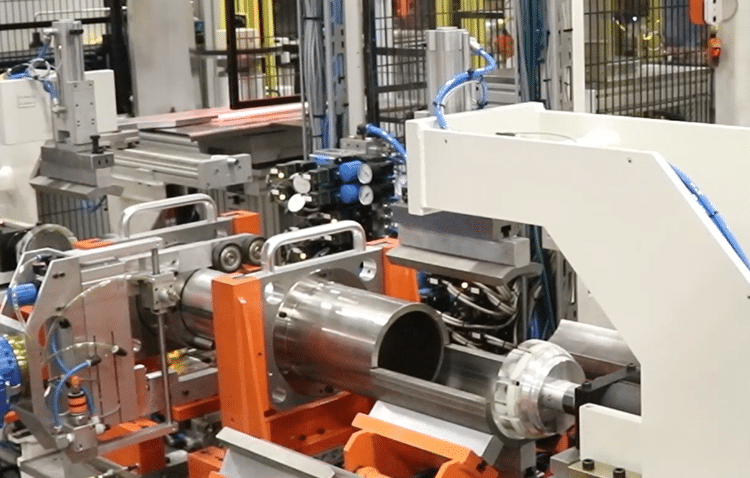

Custom Automation for Your Operation

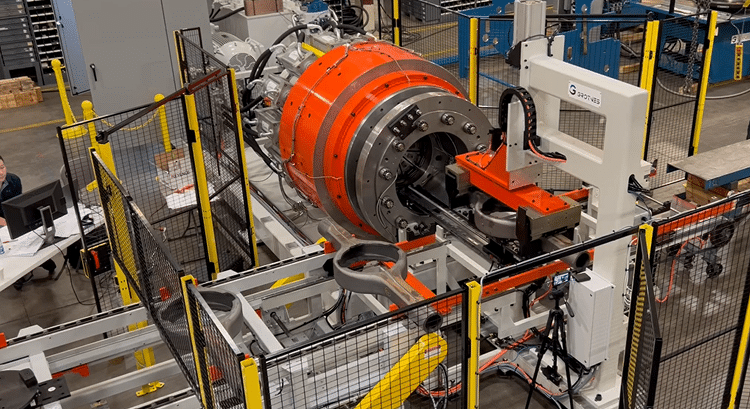

In addition to our core technologies, Grotnes can add automation to facilitate product flow and operator support.

Integrating automation into a production environment enhances efficiency by streamlining processes, reducing manual labor and minimizing errors. This leads to increased productivity, improved product quality and significant cost savings for our customers.

Applications

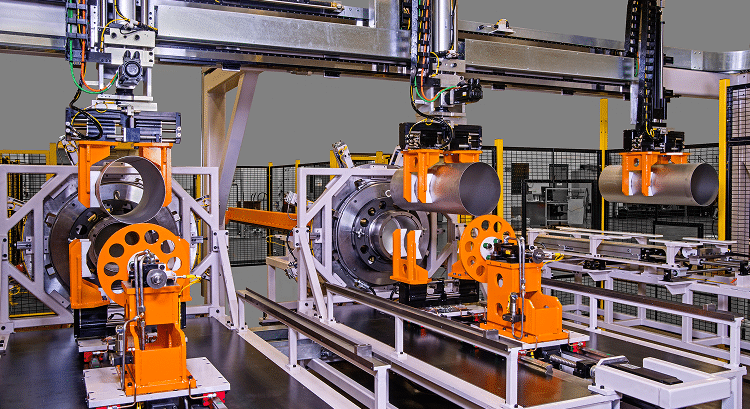

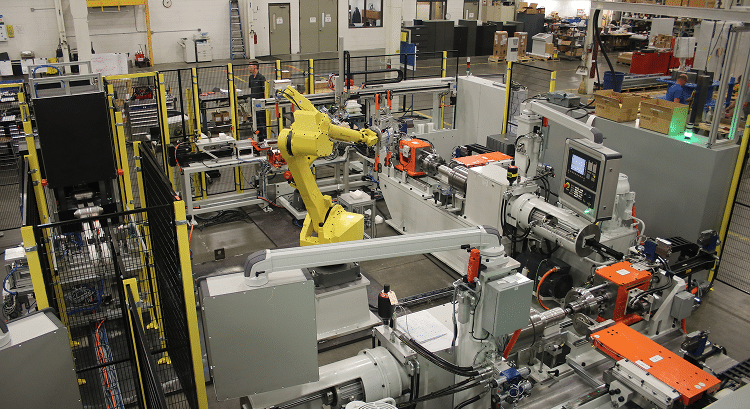

- Robots and Transfer Systems

- Conveyors

- Load and Unload Automation

- Part Buffers and Accumulators

- Singulators

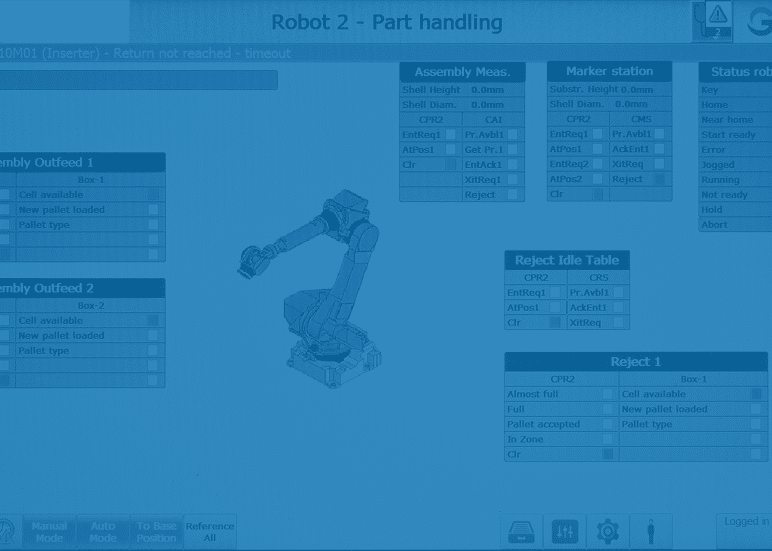

- Bar and QR Code Scanners

- Orienters and Weld Detectors

Features

- Custom designs to meet customer needs.

- Robots and stations transfer parts up, down and linearly between stations

- Conveyors use variable speed settings to match production requirements.

- All machines built to withstand heavy use and harsh environments.

- Integration with production systems for synchronized operation.

- Scanners record and track part information for quality control and traceability.

Advantages

- Enhanced Efficiency: Streamlines production processes, reducing manual labor and increasing throughput.

- Improved Accuracy: Ensures precise handling and placement of parts, minimizing errors and enhancing product quality.

- Cost Savings: Lowers operational costs through reduced labor, efficient resource usage and decreased downtime.

- Scalable Integration: Equipment easily incorporates into existing production lines, allowing for flexible and scalable automation solutions.

Quote-to-Ownership Process

1. Request a Quote

Begin your journey by reaching out to Grotnes to request a detailed quote. Provide specifics about your metalforming needs and the types of materials you will be working with, allowing our team to tailor the machinery options to your requirements.

2. Consultation

Engage with our experts during a comprehensive consultation to refine your machinery specifications and explore additional features and customizations. This step ensures the equipment you choose perfectly aligns with your production goals and operational demands.

3. Finalize & Install

Once you approve the final specifications and quote, we’ll proceed with the manufacturing of your customized metalforming machinery. After production, Grotnes will coordinate the delivery and installation, ensuring everything is set up to operate seamlessly within your existing processes.