Appliance

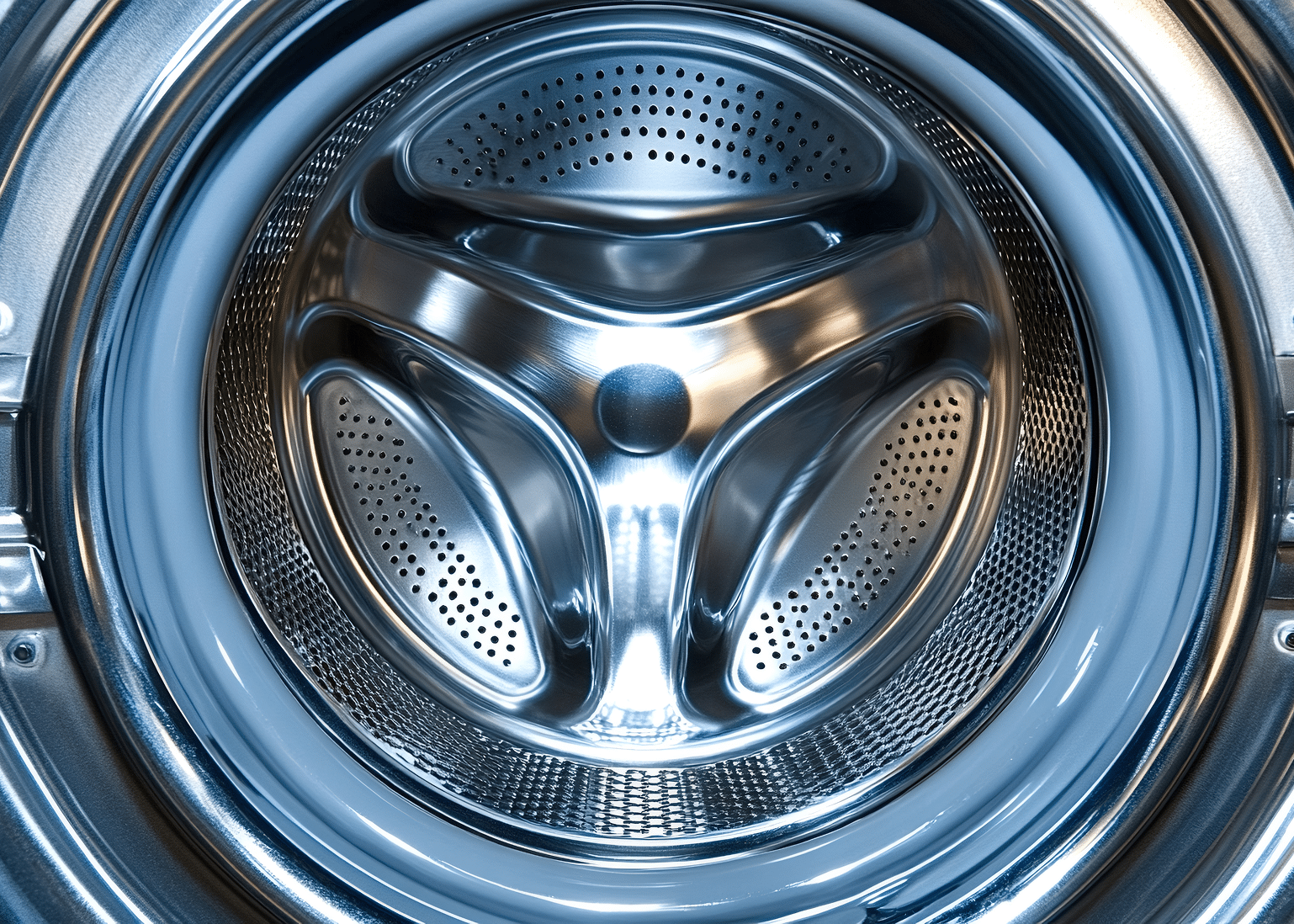

Metalforming plays a critical role in the appliance industry, shaping durable, high-precision components for everything from washers and dryers to refrigerators and ovens.

Metalforming Solutions For The Appliance Industry

Our suite of machines, including expanders, roll formers, and specialized tooling systems, enables the precise shaping of metal for washer and dryer drums, water heater combustion chambers, dishwasher components and more.

Our hydraulic expanders are integral to producing components with exact dimensions and smooth finishes. These self-contained, floor-mounted units are engineered for integration into production lines, featuring user-friendly Human-Machine Interfaces (HMI) for creating and storing part programs. They’re designed to efficiently expand metal to desired specifications with precision, ensuring high-quality results with every cycle.

Our roll formers are essential for creating complex shapes, including the precise grooves required in washer and dryer drums. Each machine, from the 400 Roll Former to our Rotating Gapless Expander Model #5-2-RHE-35-12, is equipped to handle various material specifications, offering unmatched flexibility and control in Metalforming. These machines also feature integrated part load/unload systems to streamline operations and reduce cycle times.

From initial machine demonstrations and on-site training to ongoing support and remote troubleshooting, our team is dedicated to ensuring that you achieve optimal performance and productivity.

Technology Used

Shrinking

Spinning

Expanding

Roll Forming

Request a Quote

Tell us about your metalforming challenge, and Grotnes can guide you to a solution!

Call Us!

Have a question? We want to hear it. Contact Grotnes today to speak with one of our expert team members.