CANNING

Explore the cutting-edge precision of Grotnes' canning technology, an efficient solution for the production of catalytic converters.

The Assembly Process

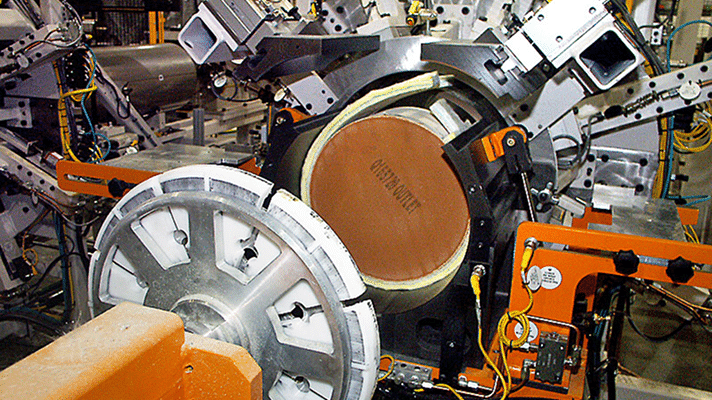

Grotnes offers both automatic and manual assembly processes for wrapping catalytic converter substrates in mats and inserting them into shells. Utilizing advanced laser measurement technology, our systems handle both hard and soft stuffing efficiently.

Applications

Grotnes canning cells are modular and designed to meet customers’ exact specifications. Depending on the determined market, Grotnes has extensive experience in passenger car, commercial vehicle and off-road emission aftermarket systems crafted to meet OEM specifications.

Features

For more than two decades, Grotnes has led the industry in size-to-fit catalytic converter assembly (canning) and pioneered many technologies such as adaptive gap control and rotary sizing. Today’s automatic canning cells are robust yet highly sophisticated and include such features as:

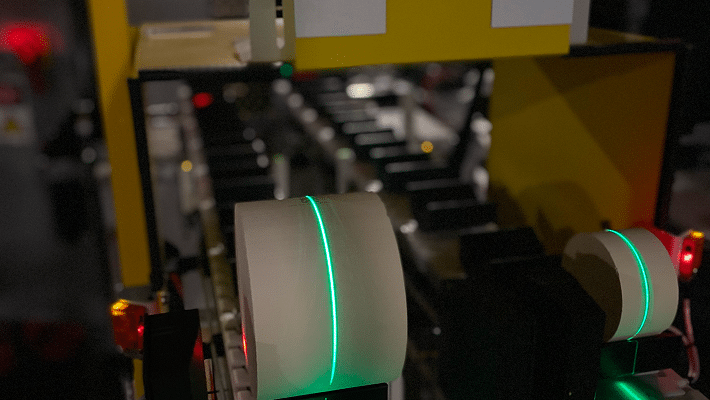

Mat and Substrate Measurement Station

Our non-contact measurement system accurately measures substrate dimensions and mat weight to industry standards. This process ensures precise determination of the target shell diameter for optimal Gap Bulk Density (GBD) and provides data for trend analysis and optimization.

Wrapping and Insertion Stations

Grotnes provides both manual and automated options for wrapping substrates. The Insertion Station, equipped to handle single or multiple substrate/mat assemblies, offers hard or soft stuffing options while monitoring position, pressure and velocity during insertion.

GBD Sizing Station

This station adjusts the shell circumference to the target diameter through two distinct methods: . Pre-Expand – Uses a segmented expander to increase the shell diameter based on precise measurements, followed by hard stuffing of the substrate/mat assembly through a funnel. Shrinking – Servo driven, cartridge style

End Sizing

Used for constant diameter end cone fit-up.

Push Out Station

Used for process verification

Part Marking

Both laser and dot peen are available

Data Tracking

Track and store process critical data for each assembly and component

Advantages

- All-Electric Servo-Driven Motion

- Manual and Automatic Equipment

- Flexible Automation

- Complete Data Tracking

- Compact Footprint

- Industry-Leading Cycle Times

- Quick-Change Tooling Including Cartridge-Style Sizer

- Tool Verification Option

Quote-to-Ownership Process

Quote-to-Ownership Process

1. Request a Quote

Begin your journey by reaching out to Grotnes to request a detailed quote. Provide specifics about your metalforming needs and the types of materials you will be working with, allowing our team to tailor the machinery options to your requirements.

2. Consultation

Engage with our experts during a comprehensive consultation to refine your machinery specifications and explore additional features. This step ensures the equipment you choose perfectly aligns with your production goals and operational demands.

3. Finalize & Install

Once you approve the final specifications and quote, we’ll proceed with the manufacturing of your metalforming machinery. After production, Grotnes will coordinate the delivery and installation, ensuring everything is set up to operate seamlessly within your existing processes.