Precision Machining

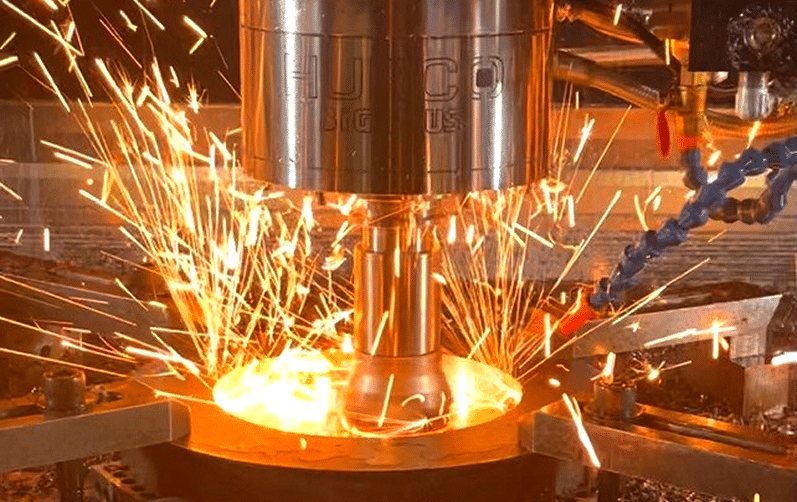

Experience unmatched quality with Grotnes’ state-of-the-art, in-house machining services, tailored to meet the diverse needs of any industry.

Precision Machining Excellence

At Grotnes, precision machining is at the core of our commitment to modern manufacturing excellence. We are recognized industry leaders, equipped with comprehensive in-house capabilities designed to fulfill the complex needs of both our products and those of our clients. The inception of our state-of-the-art machine shop was spurred by necessity during the peak of the COVID-19 pandemic, addressing the challenges of supply chain disruptions and material shortages that impacted many sectors.

Strategic Expansion of Capabilities

Confronted with these challenges, we strategically enhanced our machining capabilities, enabling us to control production timelines more effectively and reduce dependency on external material supplies. This expansion was not only a move to strengthen our own manufacturing resilience but also set the foundation to extend our machining expertise to other businesses. Through contract machining and outsourcing services, we now support a diverse range of industries, providing tailored solutions that emphasize quality, precision and efficiency.

Advanced Machining & Inspection Processes

Our machining process begins with a comprehensive review of production orders and material availability by our S&R clerks, ensuring all resources are optimally aligned for production. If materials are not prepared, they’re precisely cut to required dimensions. The material then proceeds to our advanced machining centers where it’s transformed into parts that meet exact specifications. Following machining, each part undergoes rigorous quality checks to ensure compliance with all requirements, with any discrepancies promptly addressed through adjustments or rework.

For external contracts, Grotnes implements an additional stringent layer of inspection to guarantee every part adheres precisely to client specifications. This includes detailed measurements and the use of equipment such as Coordinate Measuring Machines to validate dimensions and tolerances.

Machining Equipment List

| Axis (inches) | |||||

|---|---|---|---|---|---|

| Type | Brand | Model | 'X' | 'Y' | 'Z' |

| CNC Machining Center | Hurco | VMX84i | 84 | 34 | 30 |

| CNC Machining Center | Hurco | VMX42i | 42 | 24 | 24 |

| CNC Machining Center | Hurco | VM One | 26 | 16 | 14 |

| Boring Mill | DeVlieg | 4K-60 Spiramatic | 60 | 40 | 50 |

| Wire EDM | Sodick | ALN 800G | 31.5 | 23.62 | 19.69 |

| Surface Grinder | Gallmeyer | Livingston S20 | 6 | 18 | 18 |

| Surface Grinder | Harig | Super 612 | 6 | 12 | 12 |

| Vertical Hand Mill | Vectrax | ||||

| Vertical Hand Mill | Bridgeport | ||||

| Vertical Hand Mill | Bridgeport | ||||

| Vertical Hand Mill | Bridgeport | ||||

| Max. Ø | Max. Lg. | ||||

| CNC Lathe | Smart | NL 6000L | 37.80 | 88.00 | |

| CNC Lathe | Hurco | TM10i | 17.70 | 28.40 | |

Let’s Connect

Learn more about how Grotnes’ comprehensive suite of metalforming equipment can be customized to meet your manufacturing challenges by speaking with our team today.