SPINNING

Explore the cutting-edge precision of Grotnes' spinning technology, an economical solution for the production of metal tubing

Applications

Grotnes spinforming has focused primarily on tube forming. Our method eliminates the need for welded end cone transitions and associated assembly costs for manufacturing tube assemblies.

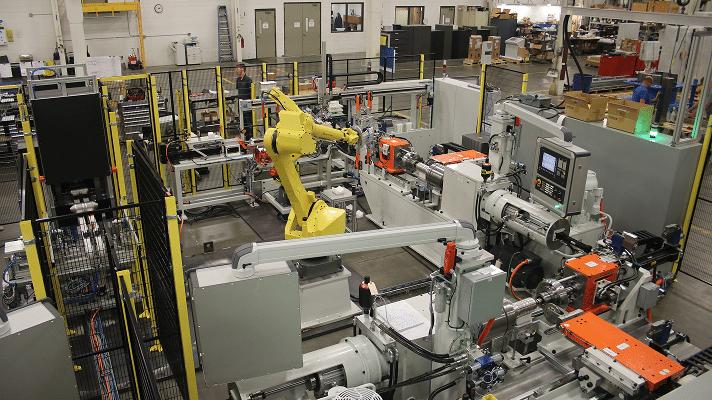

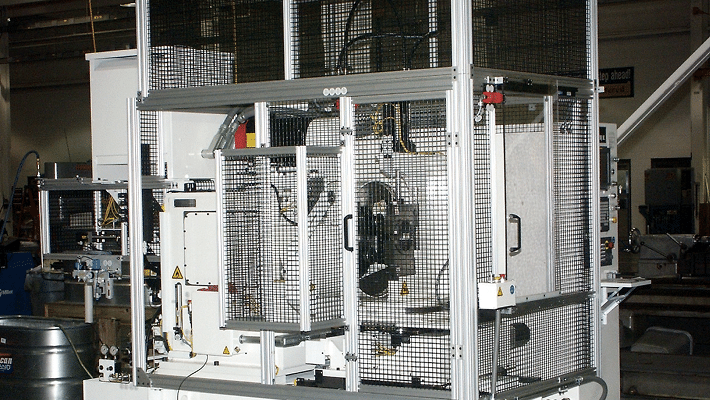

Spinning technology offers a cost-effective solution for forming both ends and the middle of a tube. Grotnes provides options for both standalone and fully-automated cells that accommodate concentric, eccentric and oblique spin-forming processes.

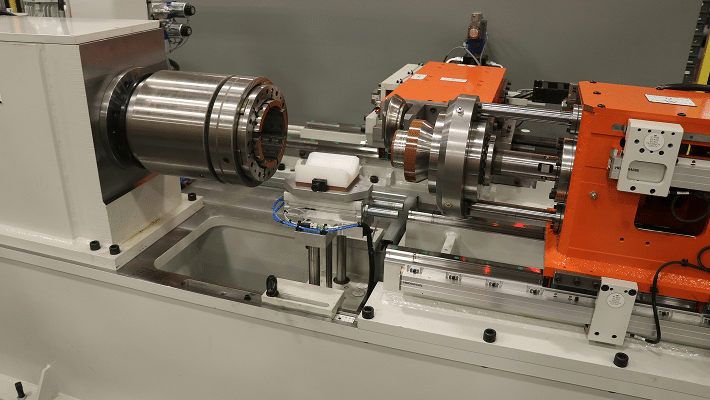

Concentric Spinning

Our concentric spin-forming machines precisely create reduced end profiles that align concentrically with the tube’s center axis. This equipment, some of which features our patented Dynamic Length Control Technology, is among the most robust in the industry and includes active tailstocks for enhanced performance.

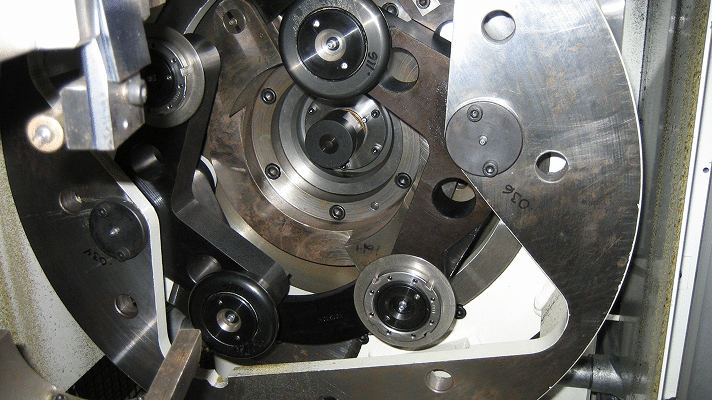

EST & OST Spinning

For more specialized needs, our Eccentric Spinning Technology (EST) and Oblique Spinning Technology (OST) allow for the formation of reduced-end profiles that are either eccentric to, or at an oblique angle from, the tube’s central axis without needing to rotate the part. These advanced machines form complex transition angles with just a simple change in the CNC program.

Additionally, EST-OST spinning machines can be equipped with automatic trimming features for the shell ends, streamlining the production process.

Advantages

- Reduced inventory

- Fewer component parts to assemble

- Decreased tooling requirements

- Lower costs for welding equipment and consumables.

Quote-to-Ownership Process

1. Request a Quote

Begin your journey by reaching out to Grotnes to request a detailed quote. Provide specifics about your metalforming needs and the types of materials you will be working with, allowing our team to tailor the machinery options to your requirements.

2. Consultation

Engage with our experts during a comprehensive consultation to refine your machinery specifications and explore additional features and customizations. This step ensures the equipment you choose perfectly aligns with your production goals and operational demands.

3. Finalize & Install

Once you approve the final specifications and quote, we’ll proceed with the manufacturing of your customized metalforming machinery. After production, Grotnes will coordinate the delivery and installation, ensuring everything is set up to operate seamlessly within your existing processes.