Expanding

From innovative design to versatile material handling and metalforming capabilities, our expanders set the industry standard for quality and performance.

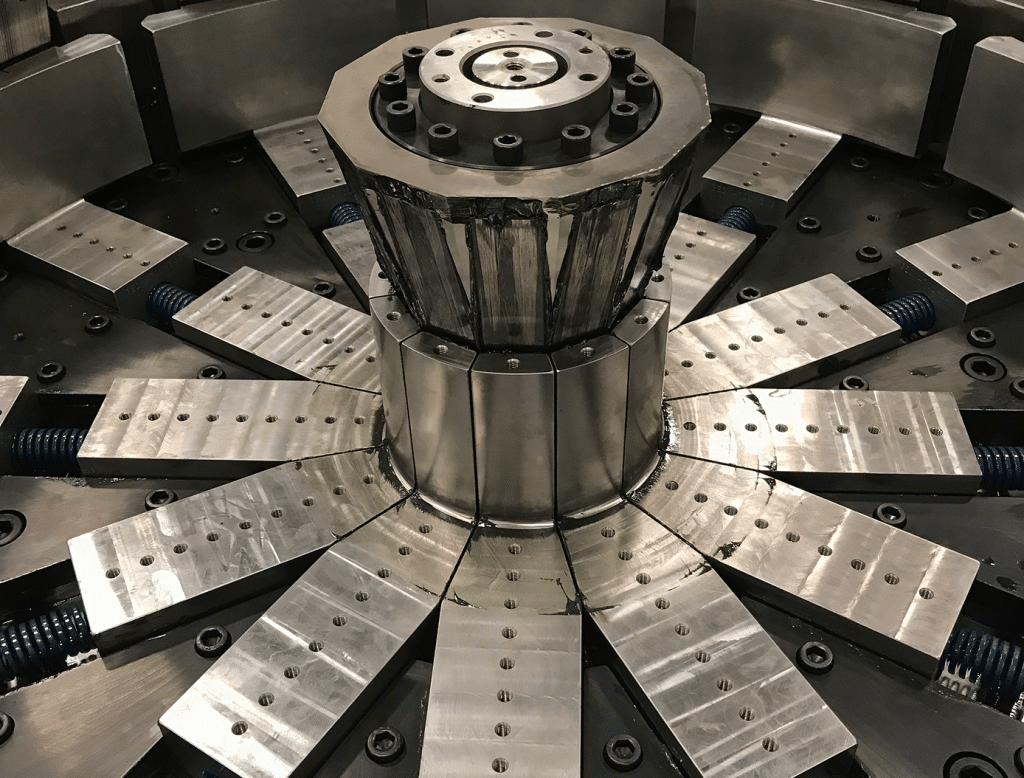

The Expanding Process

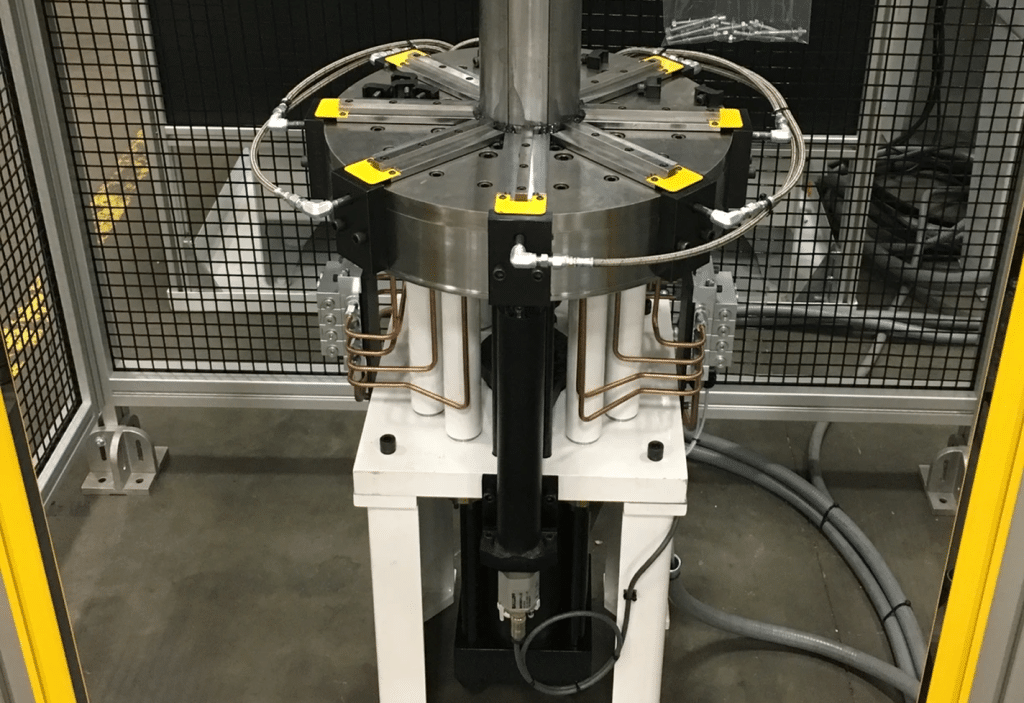

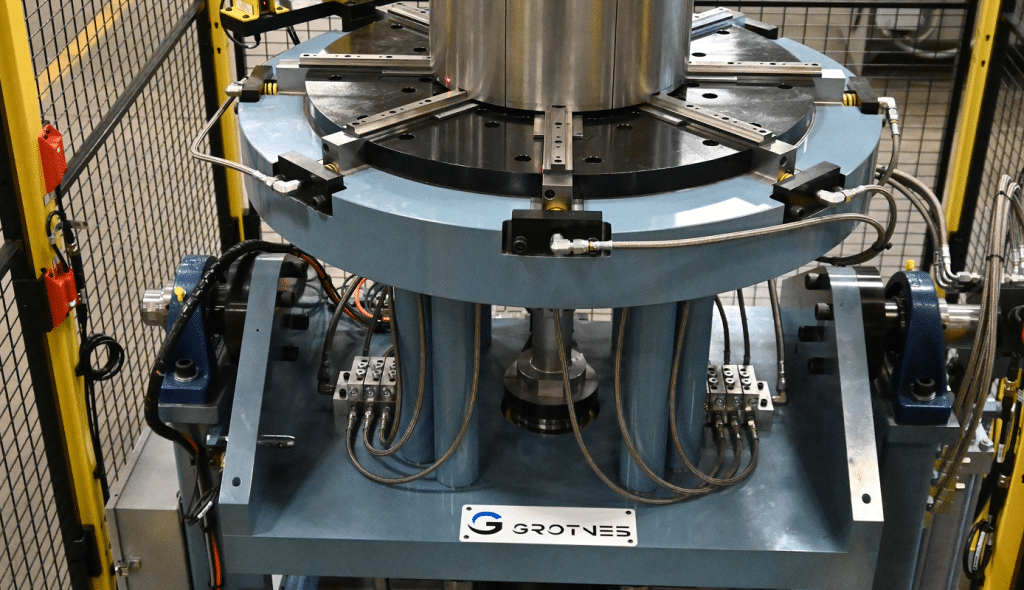

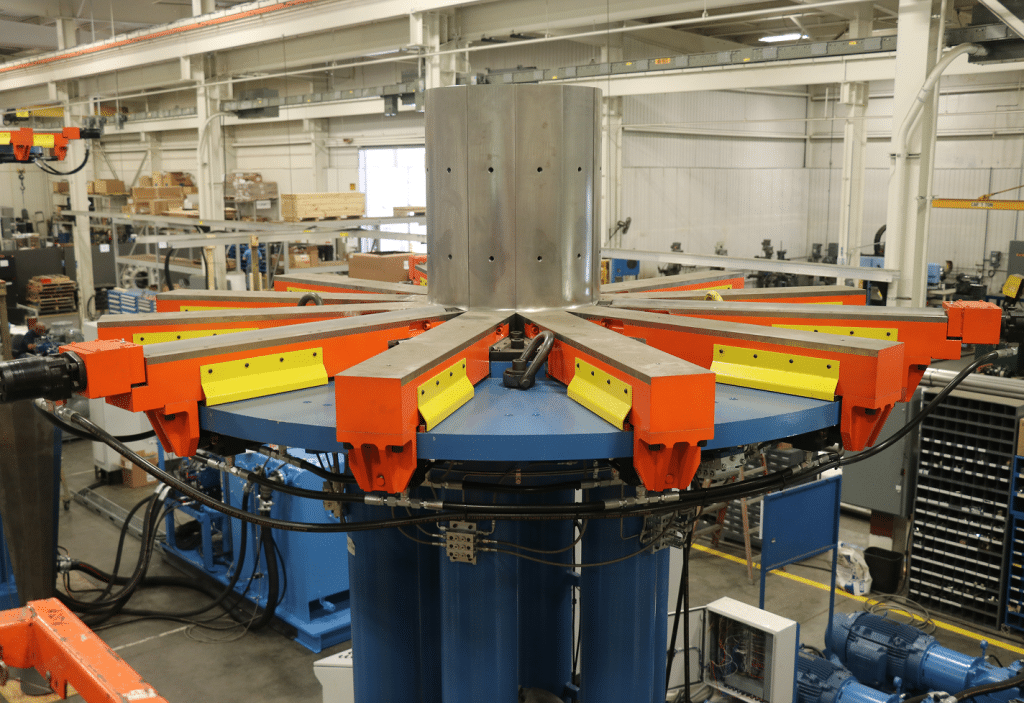

As the inventor of the expander, Grotnes machines are capable of sizing and forming a broad spectrum of hollow components — whether cold or hot — ranging from cylinders and cones to squares and various poly-sided shapes. Our expanders, available in both push or pull configurations, operating on the wedge principle. As the cone progresses, it pushes the dies outward, stretching the metal beyond its yield point to achieve the desired shape and

Expander Applications

These machines are versatile enough to handle applications involving both small, light-gauge metal parts and larger, more robust components. Suitable applications include but are not limited to: appliance housings, bearing retainer rings, blower and fan housings, and various metal containers such as conical shapes and drums up to 55 gallons — including ISO open head. They are also perfect for more demanding tasks involving heavy jet engine rings, bearings, flanges, motor and generator frames and pipe couplings.

Features

- A variety of sizes and configurations to suit every need

- Precise position control systems for exact accuracy

- Gauge mode for verification of expansion

- Modern servo pump control for energy efficiency and response speed

- User-friendly HMI touchscreen for ease of operation

- Automatic lubrication system to maintain peak performance

- Optional collapsible outer dies and heated dies with water cooling

- Efficient automatic loading and unloading to streamline the process

- Recipe-driven controls capable of customizing speeds, modes, dwell time, auto indexing, data tracking and more

- Safety features such as part temperature monitoring and tool-securing safeguards

Tailored to Your Needs

Since its original design in 1898, the Grotnes expander has been setting the standard in Metalforming. Capable of handling a wide range of materials, from steel and aluminum to nickel-based aerospace alloys and titanium, Grotnes expanders combine exceptional versatility with outstanding efficiency and are custom crafted to meet your industry demands.

Typical capacities include but are not limited to:

- Tonnage capacity ranging from less than 2 tons to more than 4,000 tons

- Diameters from 2 in to more than 25 ft

- Heights from 1/4 in to more than 16 ft

- Wall thickness from .060 in to more than 12 in

- Capabilities for both hot- and cold-forming processes

Quote-to-Ownership Process

1. Request a Quote

Begin your journey by reaching out to Grotnes to request a detailed quote. Provide specifics about your metalforming needs and the types of materials you will be working with, allowing our team to tailor the machinery options to your requirements.

2. Consultation

Engage with our experts during a comprehensive consultation to refine your machinery specifications and explore additional features and customizations. This step ensures the equipment you choose perfectly aligns with your production goals and operational demands.

3. Finalize & Install

Once you approve the final specifications and quote, we’ll proceed with the manufacturing of your customized metalforming machinery. After production, Grotnes will coordinate the delivery and installation, ensuring everything is set up to operate seamlessly within your existing processes.