Shrinking

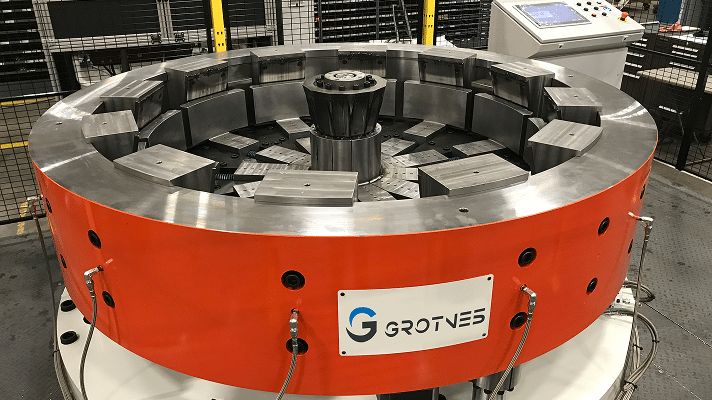

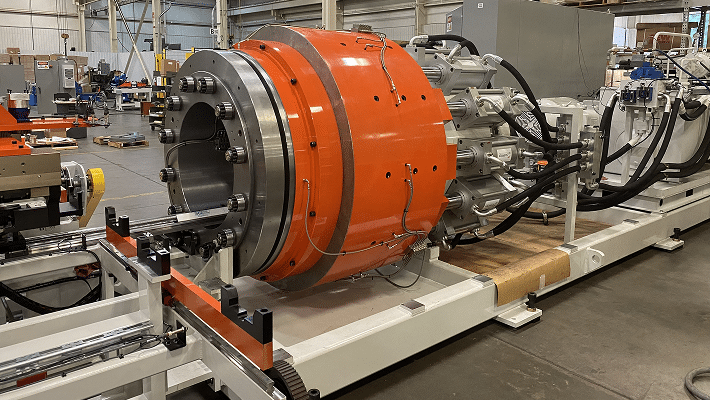

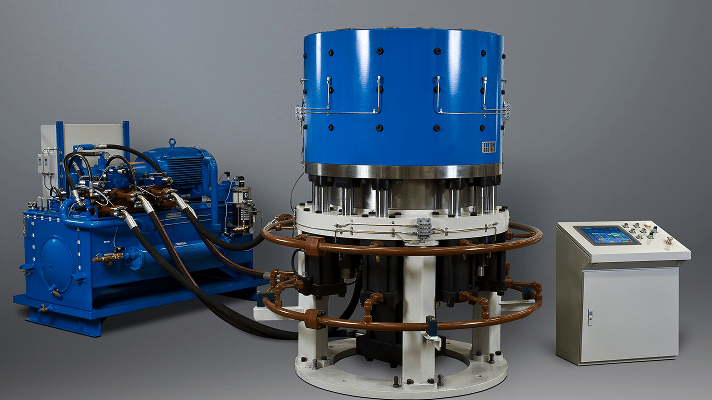

Achieve unparalleled precision and control with Grotnes' advanced shrinking technology, designed to perfect the outer diameter of diverse components.

The Shrinking Process

Grotnes shrinkers are expertly designed to ensure precise outside diameter accuracy for a variety of parts. Operating on the principle opposite to expanding, the shrinking process involves positioning the part within the shrinker with its outer diameter facing the tooling. As the dies are forced inward, they compress the metal beyond its yield point, achieving the desired shape and size.

Shrinker Applications

Widely used in applications including pipe couplings, jet engine parts, drums, exhaust components, motor frames, conveyor pulleys and bearing races, Grotnes shrinkers are essential for manufacturing a range of precise components.

Features

- Fitted with a recipe-driven controller, our shrinker/circumpress offers straightforward setup and seamless transitions between different roller sizes, streamlining production and boosting productivity.

- A light curtain and essential interlocks safeguard operators during the forming process.

- Easily interchangeable tooling enables the creation of products with various diameters and taper angles for rapid customization.

Quote-to-Ownership Process

1. Request a Quote

Begin your journey by reaching out to Grotnes to request a detailed quote. Provide specifics about your metalforming needs and the types of materials you will be working with, allowing our team to tailor the machinery options to your requirements.

2. Consultation

Engage with our experts during a comprehensive consultation to refine your machinery specifications and explore additional features and customizations. This step ensures the equipment you choose perfectly aligns with your production goals and operational demands.

3. Finalize & Install

Once you approve the final specifications and quote, we’ll proceed with the manufacturing of your customized metalforming machinery. After production, Grotnes will coordinate the delivery and installation, ensuring everything is set up to operate seamlessly within your existing processes.