Engineering Excellence Since 1898

From whiskey barrels to jet engine components, the Grotnes name carries with it more than 125 years of custom metalforming solutions, offering global services and a comprehensive suite of industry-leading equipment.

An Enduring Legacy

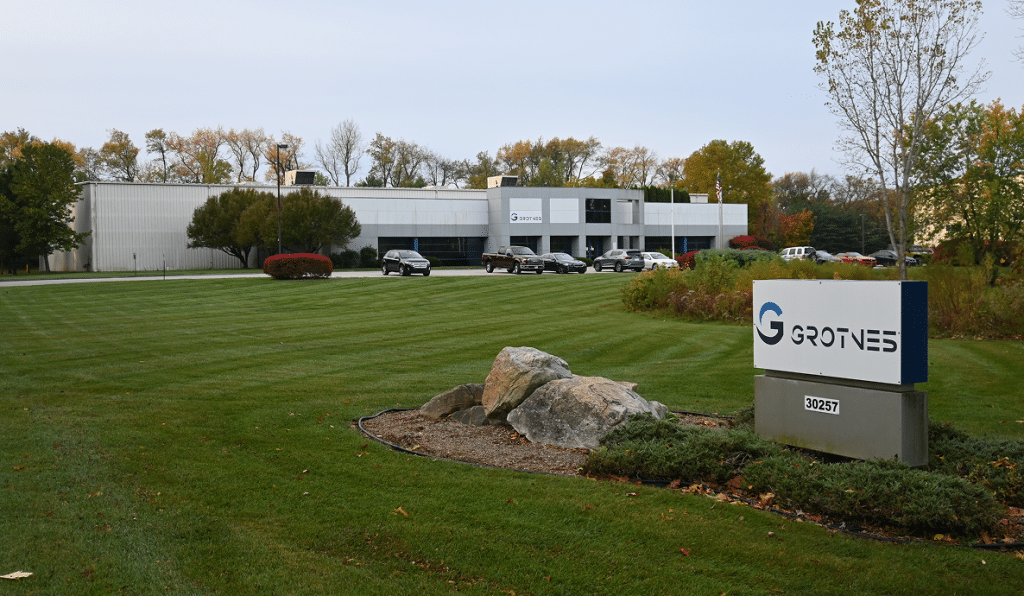

Headquartered in Niles, Michigan, Grotnes holds a pioneering past, threaded through strategic partnerships, acquisitions and a commitment to innovative metalforming solutions.

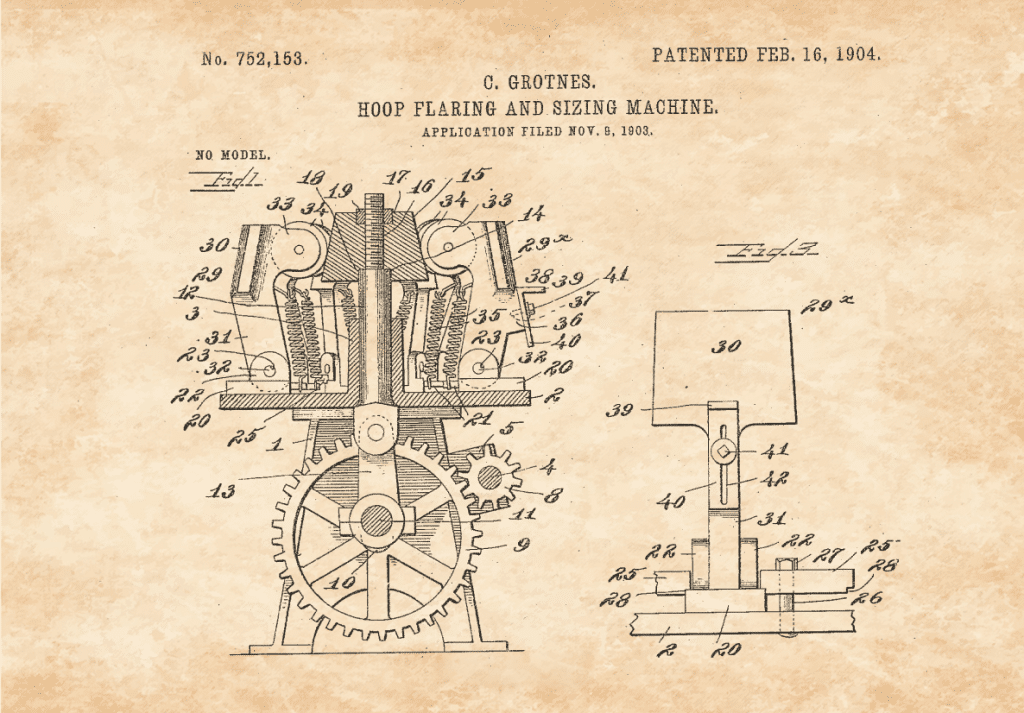

Tracing its roots back to 1898 in Chicago, Illinois, the company was initially known as “Charles Grotnes Machine Works,” later evolving into Grotnes.

Innovation in Metalforming

Charles Grotnes himself was the mastermind behind the pioneering machine, aptly named the Expander, which revolutionized metalworking by stretching and setting metal rings from simple cylindrical blanks. The machine was initially used to produce whiskey barrel rings to bind wooden staves. Beyond this, Grotnes carved out a niche in developing technologies for cold metalforming, such as shrinking and rotary rollforming.

Our Path Today

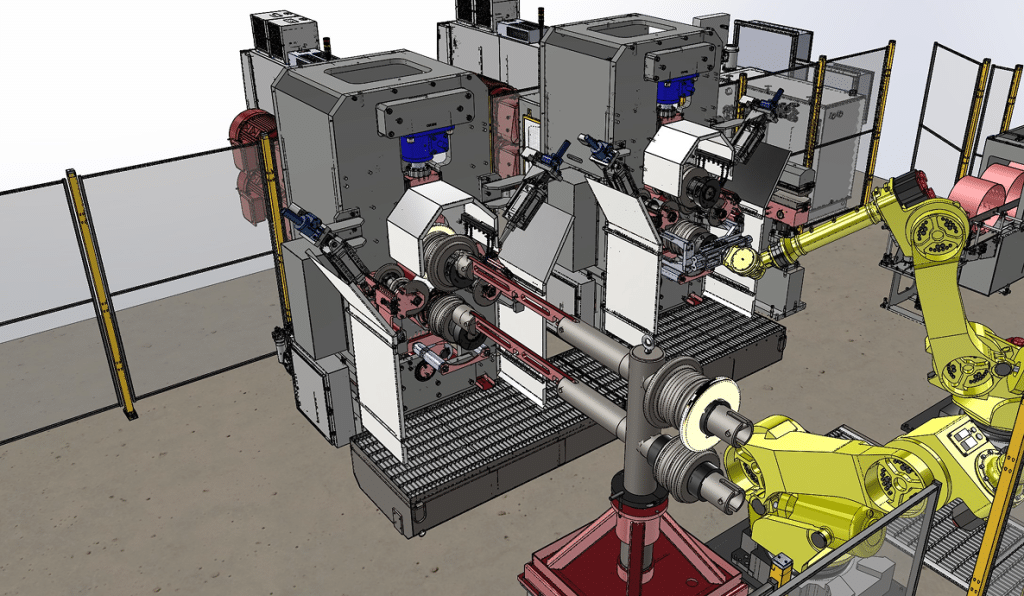

Grotnes’ reputation as an innovator in custom metalforming equipment and integrated systems now spans industries from automotive and aerospace to rigid packaging, appliances, tanks and beyond. With more than 128 years of engineering excellence, we continue to offer global support for our equipment, performing extensive retrofits and rebuilds, supplying spare parts and providing prototyping and production services through our Formitt Metal Labs division.

Let’s Connect

Learn more about how Grotnes’ comprehensive suite of metalforming equipment to meet your manufacturing challenges by speaking with our team today.