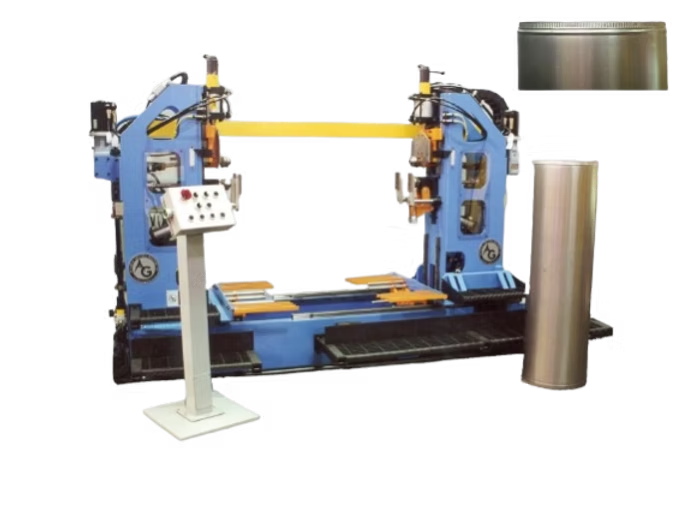

Grotnes is proud to present our jacket crimper for water heater jackets, a key machine that showcases aspects of our metal-forming technology. Designed to form end crimps simultaneously on both sides of a tank jacket, this machine helps to streamline tank manufacturing for a variety of industries’ potential use, including chemical, oil and gas, water treatment, cryogenics and more.

The Jacket Crimper at Work

Understanding the operational sequence of the jacket crimper is key to appreciating its impact:

- Loading and Alignment: Seamed jackets are horizontally loaded onto the crimper’s entry rails. These rails, angled for optimal positioning, allow the jack to seamlessly roll into the crimper’s lift stations. A stop on the entry releases the jacket in a timely manner, ensuring a smooth flow.

- Centering and Lifting: Once in place, a stop within the station accurately centers the jacket. The lift raises the jacket, aligning it precisely with the tooling mechanism.

- Internal Lifting and Positioning: The machine features a set of pivoting arms that lift the jacket’s shell from the inside. This action ensures the top edge of the jacket feeds correctly into the forming rolls.

- Engagement and Crimping: The moveable head strokes in, engaging both ends of the jacket with the form rolls. The jacket, held firmly by the pivoting arms and stop plates, is then crimped as it rotates between the forming rolls.

- Completion and Ejection: After a full rotation and successful crimping, the form rolls retract, and strippers extend to remove the crimped jacket. The lift section aids in this process, ensuring the jacket is smoothly transitioned out of the machine.

This operation is enhanced by the crimper’s automated adjustment system, requiring minimal operator input. Parameters such as jacket diameter and length are easily set via a touchscreen interface, with the machine automatically adjusting its components. However, the depth of the crimp is manually set using threaded stops, which dictate the upper form roll cylinders’ final position. The crimper is also compatible with future form roll profiles with diameters between 4” and 3”, adding to its versatility.

Industries Benefiting from the Jacket Crimper

The Grotnes jacket crimper is a resourceful machine potentially beneficial to a range of industries, including but not limited to:

- Construction

- Energy

- Oil & Gas

- Water Treatment

- Cryogenics

How Grotnes Can Help

Grotnes stands at the forefront of creating specialized, high-quality jacket crimpers and related equipment tailored to the diverse needs of industrial manufacturers. Recognizing each customer has distinct requirements, Grotnes excels not only in machinery production but also in offering expert guidance and consultation, as well as prototyping.

Our team is adept at understanding specific operational needs and guiding customers toward the most suitable jacket crimper or other custom-made machinery for their particular application. Through consultation, feasibility studies and more, our process ensures each customer receives a solution that is not only effective but optimized for their manufacturing operation.

Connect with Grotnes today and learn more about our comprehensive line of metal-forming equipment!